- #Cnc usb controller firmware download how to#

- #Cnc usb controller firmware download serial#

- #Cnc usb controller firmware download software#

- #Cnc usb controller firmware download Pc#

If we tried to communicate via USB by means of an adapter, there could be – because of the latency – some synchronization problems among the pulses (since Mach 3 commands the motors via the parallel’s pins and the lines via drivers) and temporal coherence. In practice, Mach 3 executes the G-code and emits specific pulses for the motors, one for each parallel’s pin, and they are synchronized and temporally coherent among them.

#Cnc usb controller firmware download software#

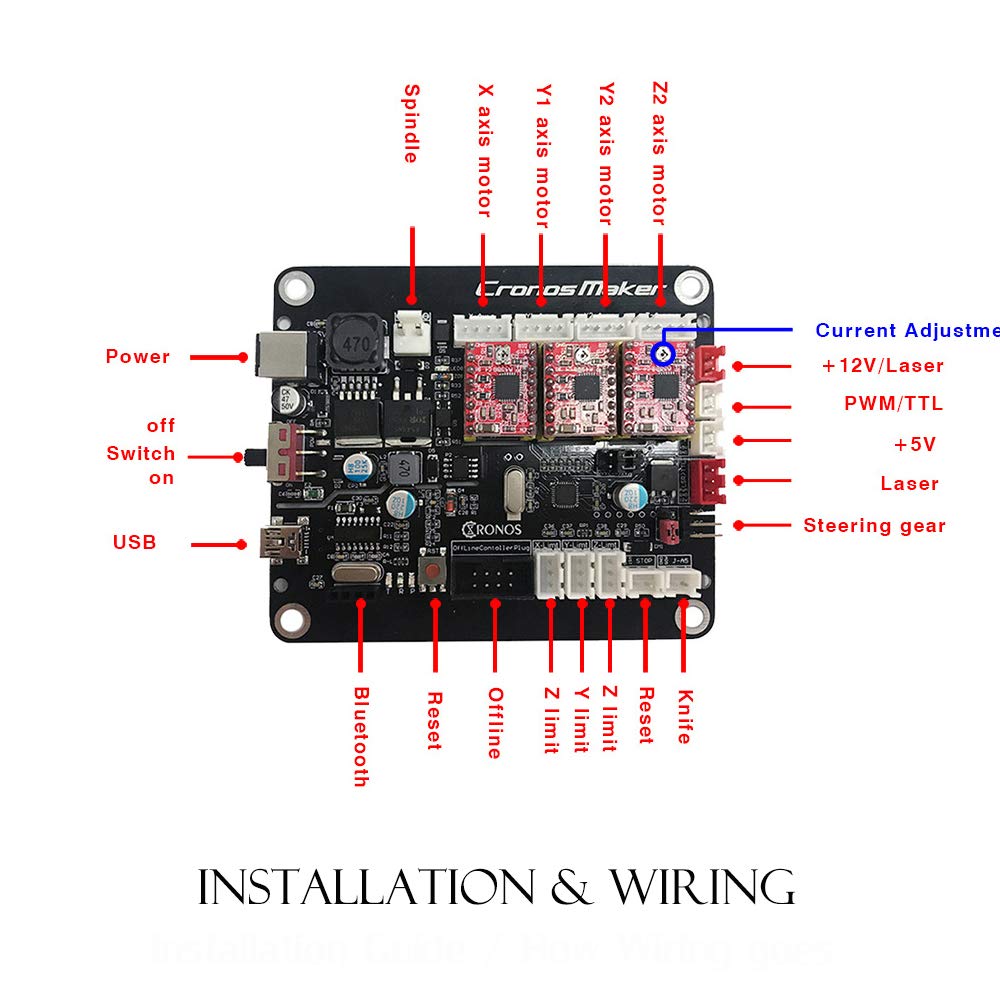

In order to understand the usefulness of the interface, it must be said that – in common CNC machines that work on LPT port – the command is usually given by the manufacturing software (e.g.: Mach 3) that starts from the file in the G-code language and extracts the pulses and sends them directly on the lines of the parallel, so to make the corresponding axes advance for a certain number of steps/mm. It, therefore, enables to keep the original electronics and adds a device that is something more than a simple interface. On the other hand, our proposal is that of a hardware that – by starting from the USB and by taking advantage of the open source software – enables to reconstruct the command pulses for the CNC control board on the machine.

#Cnc usb controller firmware download serial#

We created this specific board since – in order to manage the CNC machine via USB – it is not sufficient to use a traditional USB/parallel adapter in fact, as the data would be sent on a virtual LPT and in serial form (since the USB is a serial) and then recomposed in parallel form with a certain delay or, worse, with unequal delays among the bits: this would bring to a situation with movements on the three axes that are not perfectly synchronized, and therefore to mistakes when manufacturing the workpiece. Since many desktop PCs and all the notebooks no longer have a parallel port, we thought to a solution that will be described in these pages, and that enables to directly drive it via USB, and therefore by means of all the modern computers.

#Cnc usb controller firmware download how to#

In this article we will show you how to use it, for the purpose of engraving printed circuit boards by means of an open source software and a refined hardware solution that enables the management via USB, from the PCs that do not have a parallel port.Īs with most CNC machines, even ours is supplied with a 3-axes control board that is interfaced to the parallel board, so that it is possible to drive it by means of software of the Mach 3 kind, that converts the G-code into pulses that are directly produced on the parallel port. It is then surely possible to work with wood and, without overdoing it, it is possible to engrave (but at a low depth) aluminium plates. This machine, that stands out for the excellent value for money (which is suitable for an amateur CNC machine) has been thought mainly for engraving plaques (such as those for the mailbox, the intercom, the door) and plastic elements (even in POMs, Delrin included). In this post you had the chance to learn about and to evaluate our new CNC milling machine, equipped with a 9,000 rpm electro-spindle and with a compact PVC chassis, and available in assembly kit.

#Cnc usb controller firmware download Pc#

The controller's primary task is to receive conditioned signals from a computer or indexer and interpret those signals into mechanical motion through motor output.Let’s print the PCBs by means of our CNC machine, that this time has been fitted with a controller that connects to a PC via USB, that draws the control signals and that regenerates timed pulses, simulating the parallel port. A controller completes the all important link between a computer system and the mechanical components of a CNC machine. The CNC controller is the brain of a CNC system. It is used to automate the creation of the control program (G-Code) that instructs the CNC machine where to position and move the cutting tool and control other aspects of the machining process. What is cnc mill program?ĬNC Milling software is also referred to as Computer Aided Manufacturing (CAM) software. In general terms, CNC stands for Computer Numerical Control and has been around since the early 1970's (often referred to as NC programming). Each unique part requires its own CNC program. This is cloud-based software that combines mechanical as well as industrial designs.ĬNC programming software creates program codes and instructions used to run a machine tool controlled by a computer. AutoCAD is the most popular CAD software for 2D and 3D drawings. Rhino3d is mainly used to create and edit surfaces, meshes, curves, and solids. Frequently Asked Questions What software do i need to use a cnc?ĥ Best CAD software that support CNC Machining

0 kommentar(er)

0 kommentar(er)